In addition to the many deposit promotions provided regularly, you can use Silver Oak Casino no deposit bonus codes in the USA. This promo offer is in high demand among casino customers, as it allows you to get free cash and make real money bets without investments. However, to withdraw bonus funds, you have to make a deposit, as there are wagering requirements set.

No Deposit Bonus Codes at Silver Oak Casino Explained in the USA

This is a bonus type you do not need to pay for; the only necessary thing is to register on the online casino’s official website. With the help of this gift, you can test slot machines for free without financial risk, as even if you lose the whole amount, you do not need to return the money. Using a no deposit bonus is different from playing in demo mode: with a gift, you can get a real payout and withdraw it, unlike in demo mode. However, to cash out winnings from a no deposit reward, you need to make a deposit and spend a specific amount of money according to the wagering requirements.

No Deposit Bonus Terms & Conditions

Terms and conditions are set by the casino to protect itself from unfair USA players who engage in multi-accounting and bonus hunting. You can find all the rules in the promo description or the Promotions section.

There are different wagering requirements for different game categories.

|

Wagering Requirement |

Games |

|

x30 |

Slots, bingo, keno, and scratch cards |

|

x60 |

Video poker and blackjack |

Wagering requirements follow the only goal: not to let customers activate the bonus and immediately withdraw the money.

Remember that you cannot wager the bonus in craps, baccarat, War, Pay Gow poker, roulette, Sic Bo, and the Shooting Games category. Your bets in these games are not counted towards wagering.

The maximum prize amount you can withdraw is $100. Free chips of $50 and more are given, and they also have a withdrawal limit of $100. Even if you manage to win more, you cannot withdraw more than the limit set, and it is also impossible to activate several no deposit bonuses simultaneously. Find out more details on the page – https://slotsandcasinos.org/casino-silveroak/.

Types of No Deposit Bonuses for USA Players

There is only one type of no deposit bonus available at Silver Oak online casino: the cash gift you can receive after redeeming a promo code. You can find them on the page with the no deposit bonus conditions.

Sign Up No Deposit Bonus at Silver Oak

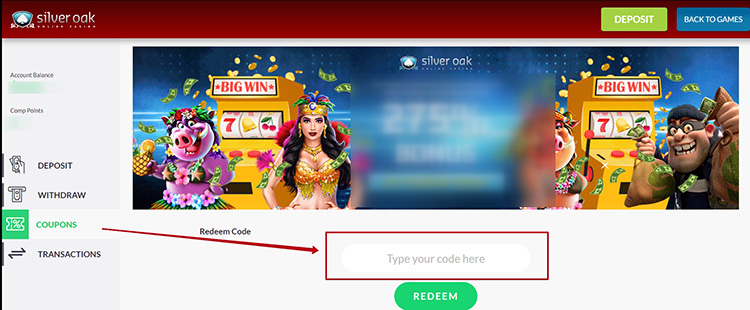

You can get $25, $50, or $100 as a no deposit bonus, and the exact free chip value depends on the promo code you use. All current no deposit bonus codes at Silver Oak Casino for USA users are located in the Coupons tab of the Cashier section. To activate the no deposit reward, follow simple steps:

- Sign up to the casino website if you do not have an account yet, specifying the requested personal information.

- Install a separate app on your PC; you can find the link for download in the main menu.

- Sign in.

- Find the Cashier section and open the Coupons tab.

- In the “Type your code here” field, enter a selected promo code.

- Press Redeem.

After that, the gifted money is credited to your bonus balance, and to withdraw it, you need to meet a x30 or x60 wagering requirement, depending on the game you prefer.

Free Spins

At Silver Oak, you cannot get free spins as no deposit bonuses. However, in the future, the casino may hold temporary promotions with promo codes where you will be able to receive free spins without making deposits.

Bonus Rounds

Some of the slots presented in the online casino lobby provide bonus rounds: free spins, risk games, or other raffles that launch when certain conditions are met. For example, if 3 scatters come up in a row, a round with 10 free spins launches.

However, there is a little but important detail: these bonus rounds are built in by providers, and this is not a casino reward.

Game Specific Bonuses

You can use the money provided as part of the no deposit gift in slot machines, video poker, roulette and other table games, keno, and bingo. The same games, except roulette, are also available for wagering the bonus.

VIP Promotions

There are no VIP no deposit bonuses at Silver Oak Casino; customers can only accumulate comp points in the loyalty program and exchange them for real money. However, we can not call it a no deposit gift because you receive points for playing for real money, so you spend it anyway and make deposits.

Guide for Claiming No Deposit Bonuses for Americans

You can use several sign up bonus codes with no deposit at Silver Oak; all of them have the same conditions. To get and activate them, you need to open the casino site and open the Inclave registration form to specify your full name, e-mail address, phone number, date of birth, country, city, and residence address.

You can sign in using your login and password specified during registration. After logging in, enter a promo code to activate your no deposit bonus; you can do it in the Coupons tab.

There is a special field for specifying a bonus code. You get the money to your bonus balance and can spend it in slots and other casino games.

If you lose the bonus amount, there is no need to wager it. You have to meet wagering requirements only if you manage to earn with the no deposit gift.

Tips for Using No Deposit Bonuses to Maximize Winnings

Before activating the no deposit promo, we recommend learning its terms and conditions. Check the bonus content, the maximum winning amount, and the wagering requirement, and then assess whether they are accessible and you can wager it.

The online casino offers $25, $50, and $100 as a no deposit, and it may seem that the larger the amount, the better the offer. However, wagering $100 is more difficult as you have to spend $3,000 or $6,000 before withdrawing, and for a $25 bonus, you only have to spend $750 or $1,500.

To get the most out of Silver Oak no deposit bonus codes, spend the gifted funds in slots with high RTP and extra rounds. It is allowed to play progressive slots using the bonus, so you can try to hit the jackpot.

FAQ

Can I grab the no deposit bonus on a mobile phone?

Yes. The list of available bonuses is the same on the desktop and mobile versions, as well as the wagering requirements.

Can I activate three no deposit bonuses for different amounts at once?

No. Only one bonus can be activated at a time; you need to wager it before activating the other.

What is the wagering requirement?

It depends on the game: it is x30 for slots and keno and x60 for video poker and blackjack.

What are other bonuses available at Silver Oak?

This is a welcome package for the first 10 deposits, 30-50% cashback, a loyalty program, and several temporary promotions.

Can I get the no deposit bonus multiple times?

This promotion is valid only once for one customer; registering multiple accounts for reactivation is prohibited by the casino rules.